ATT Cheshire

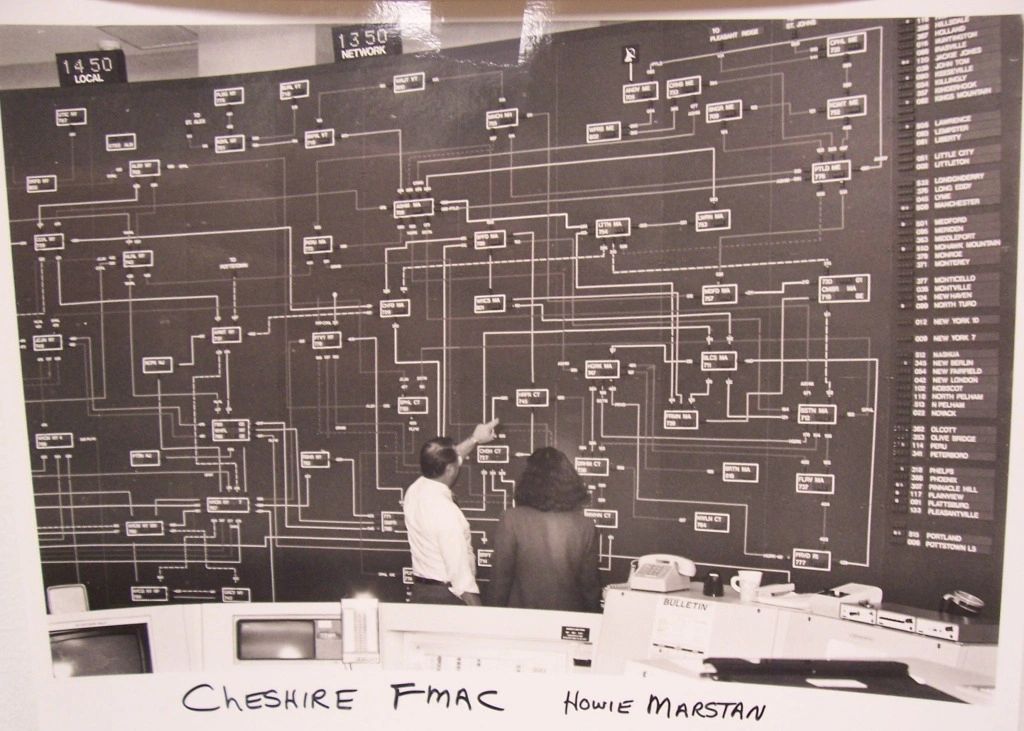

The Cheshire ATT facility is an underground complex originally built in 1966. It was an underground terminal and repeater station for the hardened analog L4 carrier cable (coax) that went from Miami to New England carrying general toll circuits and critical military communication circuits. It reportedly housed an AUTOVON 4-wire switch as part of the switching fabric of that critical global military communications network. Cheshire also connected via terrestrial microwave to the major, semi-hardened AT&T Durham station which linked to many other sites including paths to New London (Navy Sub base) and to Green Hill, RI to meet a transatlantic cable to Europe.

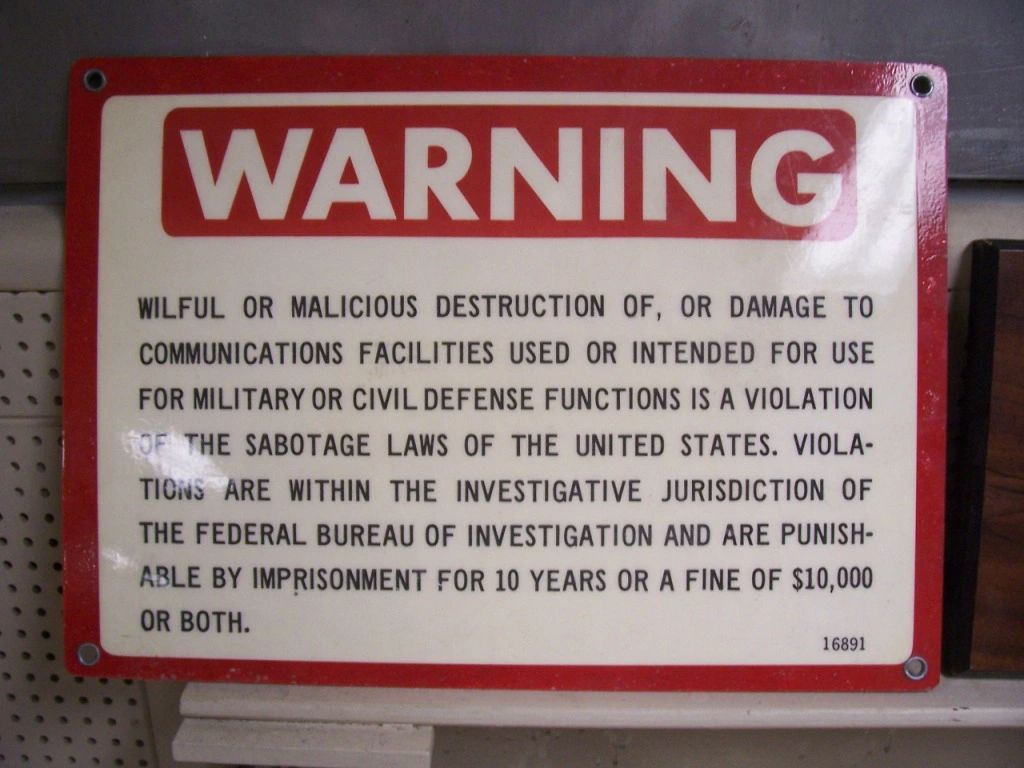

The Official ATT facility description from 1966:

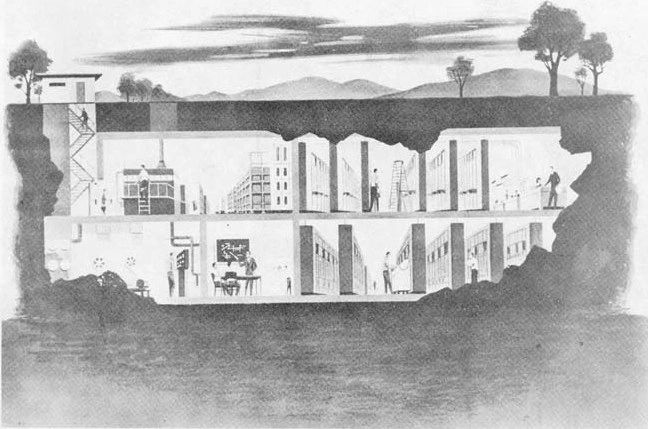

The Cheshire central office is a two-story underground, hardened building owned by Lone Lines and located in Cheshire, CT.

This office is manned 24 hours daily. The Plant Manager has a staff comprising four Plant Supervisors and eighteen Craftsmen.

Cheshire serves as a metropolitan junction station for Hartford and New Haven and as a junction point and Powercenter for 20L4 coaxial cable on The Boston-Miami route, The 20L3 Chesterfield-New Haven route, the 6L4 Green hill, R.I.-Cheshire, the 12L3 Cheshire-Hartford cable and a TD2 route to Durham via Little City. It also has a #1 ESS Machine on The Autovon Network.

Located on a mezzanine floor is The Northeastern Area Restoration Center, manned 24 hours daily. It's Plant Manager has a staff comprising six Plant Supervisors and Six Craftsmen.

See also:

http://www1.shore.net/~mfoster/Cheshire.htm

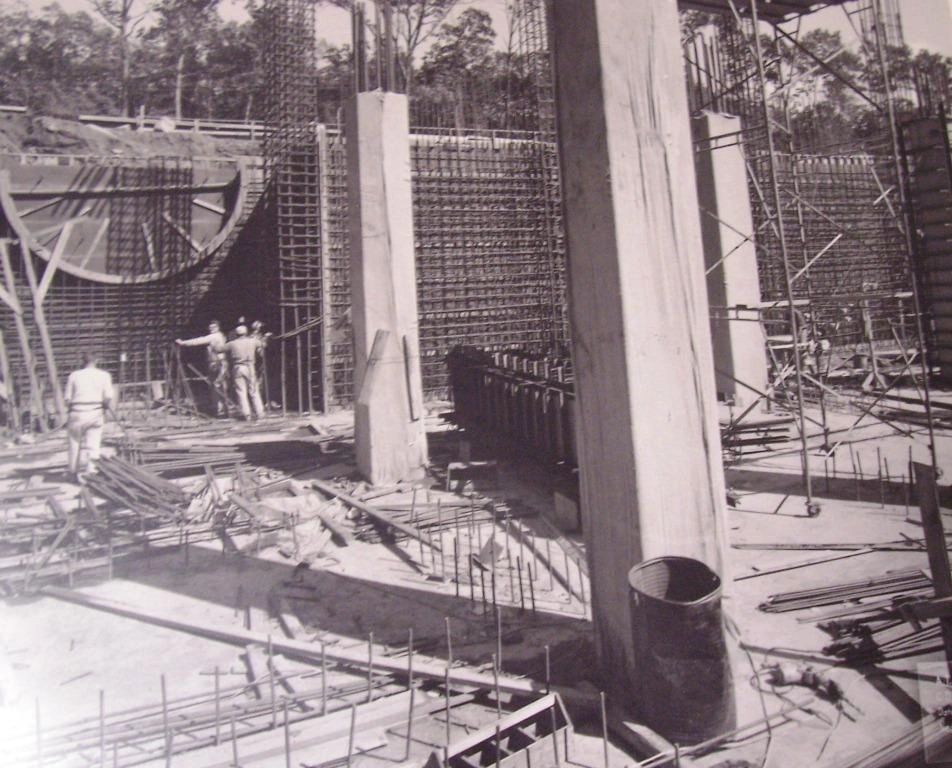

Construction Phase

The circular cut-out on the left in the above photo is for one of several air intake tunnels.

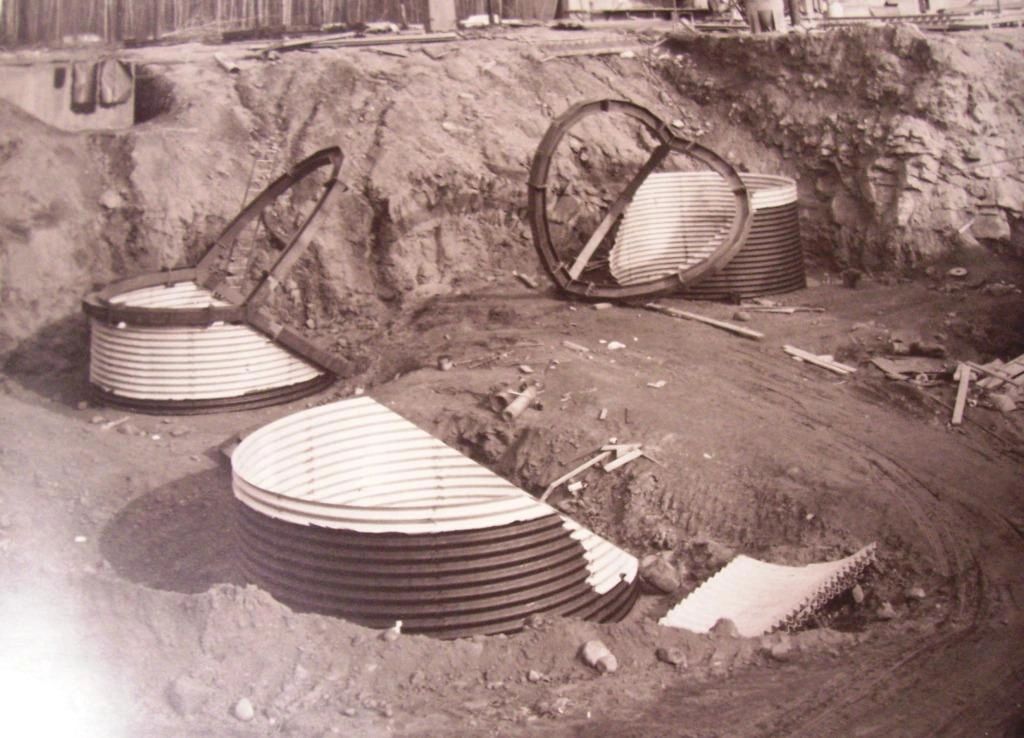

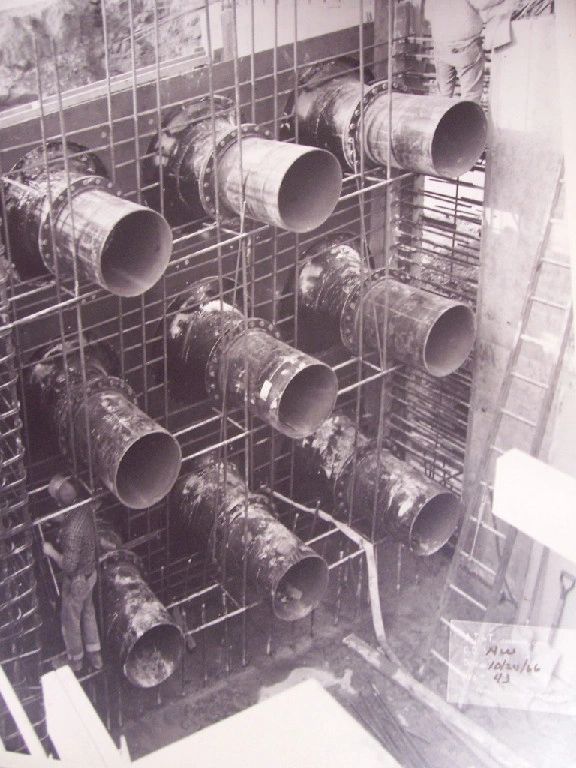

The large corregated metal pipes in the above photo are air intake and exhaust tunnels.

(see below).

Louver type blast valves.

Redundant chilled-water system.

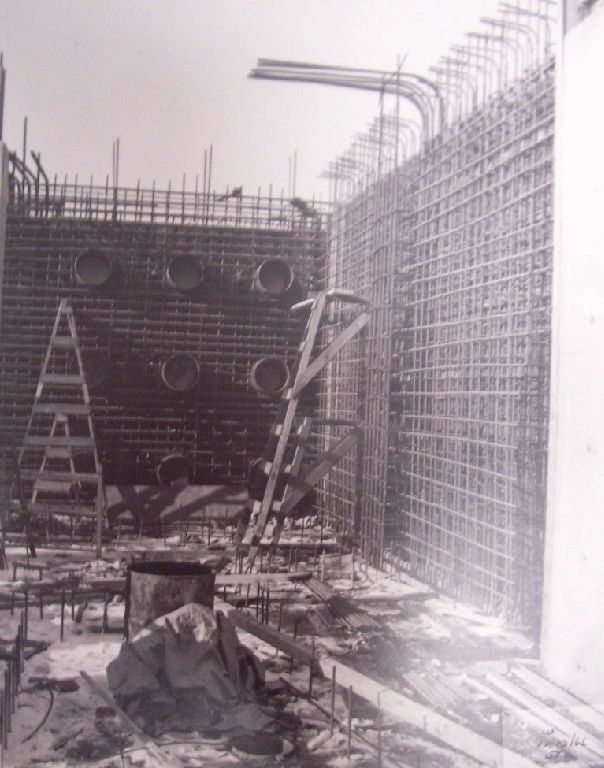

Massive amounts of rebar were used to reinforce the concrete.

The round penetrations allowed outside air and exhaust to enter/leave the building and supported blast valves on the exterior.

When the facility was finished it was covered with a minimum of 10 feet of earth.

The next four images show the huge air intake and exhaust tunnels. Also visible in the first photo are the fresh water tanks on the left and the four 45,000 gallon generator fuel tanks in the background.

In the foreground: the air intake tunnels

On the left, two fresh water tanks.

Generator fuel takes are in the background.

Air intake and exhaust tunnels.

Intake and exhaust.

Four 45,000 fuel gallon tanks with 180,000 gallon capacity to power the huge generators which would provide emergency power during power outages and when the facility was locked down.

Blast valves being installed on the air intake. You can judge the size by

comparing the valves to the two workers in the image.

Sewage ejector system.

Two of the huge air handling blowers can be seen in this picture . . . part of the massive

chemical, biological and nuclear air filtration system.

One of the three generators ready to be installed. These units were gas-turbine and

manufactured by Solar Crop.

Kitchen facilities were provided as the workers would have to shelter on site for up to 30 days.

Even the plumbing fixtures are on springs and utilize flex joints so that they will still function after the shock wave from a nearby nuclear detonation occurs.

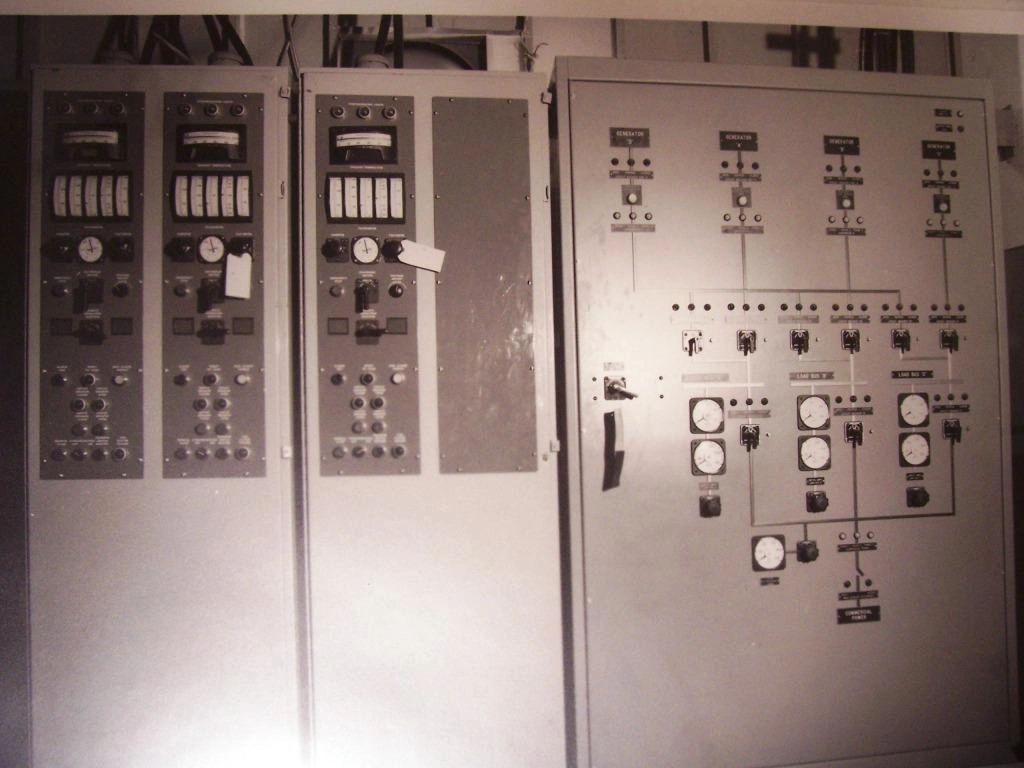

One of the original racks hanging from the ceiling by springs.

1971 image of the Cheshire control room.

Interior:

After checking in with Security and getting buzzed in through two above ground doors it's time to go down the stairs, six flights of them!

One of the first things that you'll notice as you go down are the interesting lighting fixtures hanging from the ceiling by springs to provide shock protection.

Originally these two solid steel blast doors were mechanically interlocked so that only one could be open at a time to provide overpressure protection from a nuclear blast.

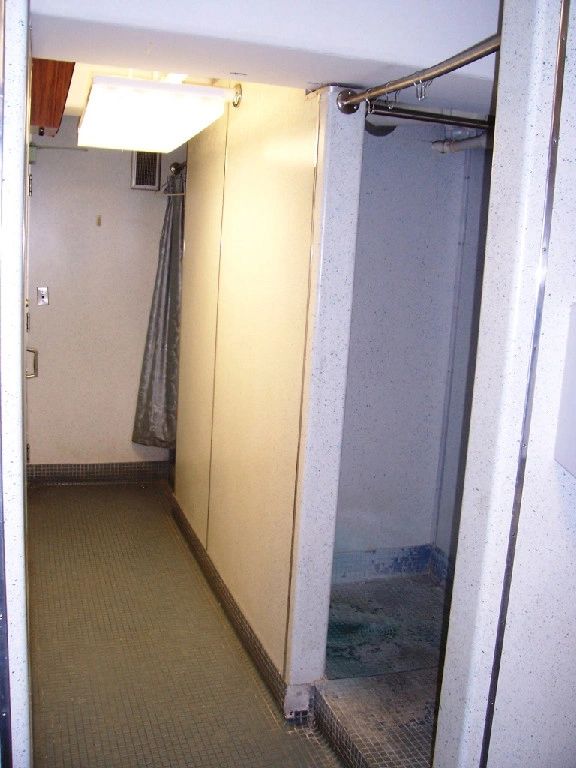

First stop is the decontamination shower.

Once inside you'll notice that all of the original equipment is mounted

to the structure with large springs.

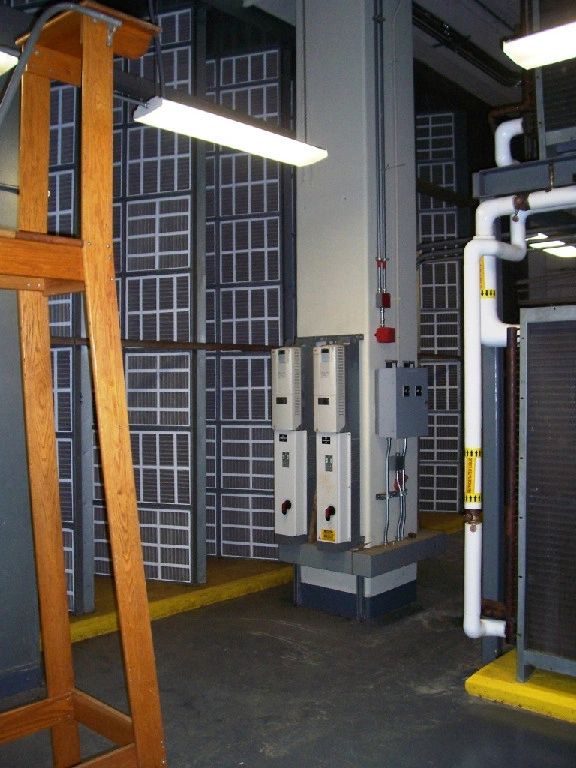

The facility's air handling system is immense. The heat load produced by the equipment required that a significant amount of air be moved into the building, filtered, cooled and either humidified or de-humidified. The requirement to remove waste heat was just as stringent.

Air is drawn into the facility via three huge intakes such as the one below.

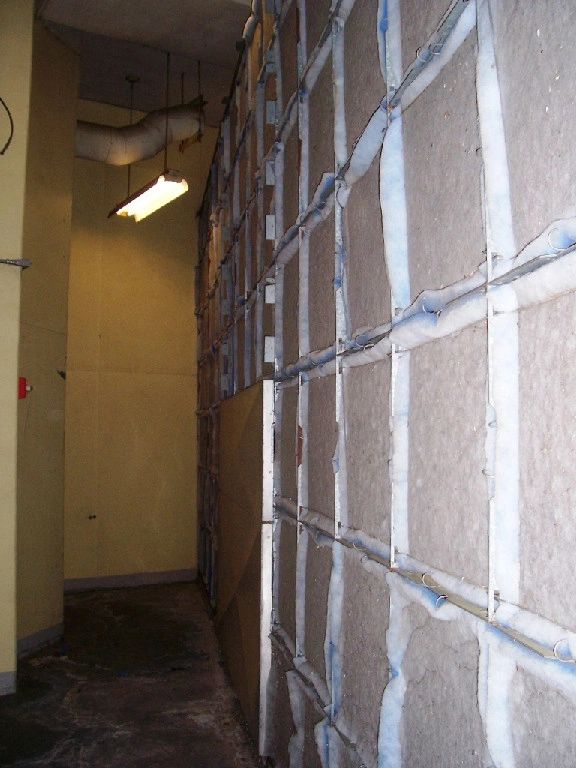

The above ground vents lead into these huge ventilation tunnels.

The tunnels originally had incredibly heavy duty blast valves connecting them to the facilities interior. The valves have been removed and an access passageway has been cut through the exterior wall of the structure. Note the thickness of the outer wall.

The facility utilized a sophisticated air filtration system that would filter out

chemical, biological and/or nuclear contamination.

Just some of the dozens of battery banks.

We've seen these spring-mounted toilets at other hardened facilities!

Above: Another ventilation tunnel.

One of three 750kVa gas-turbine gensets.

The actual turbine engine is surprisingly small.

Generator exhaust stacks through wall.

The gensets exhaust into the HVAC exhaust tunnel.

Spring mounted redundant water pumps.

Part of the "CBR", chemical, biological and radiological air filtration system.

Extremely heavy blast door leading to the hoist chamber.

Note the thickness of this door and the latch mechanism.

Once unlatched it took an immense effort to push the door open

due to its weight even though it was well balanced.

Note the size of the hinge.

Kitchen and cafeteria.

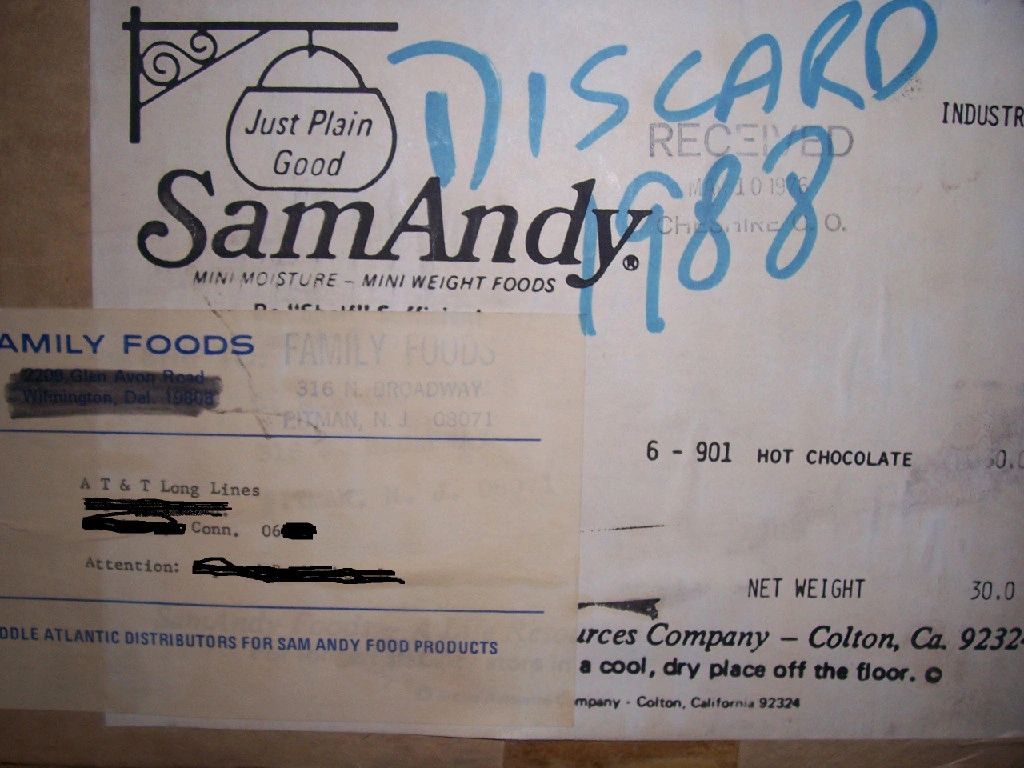

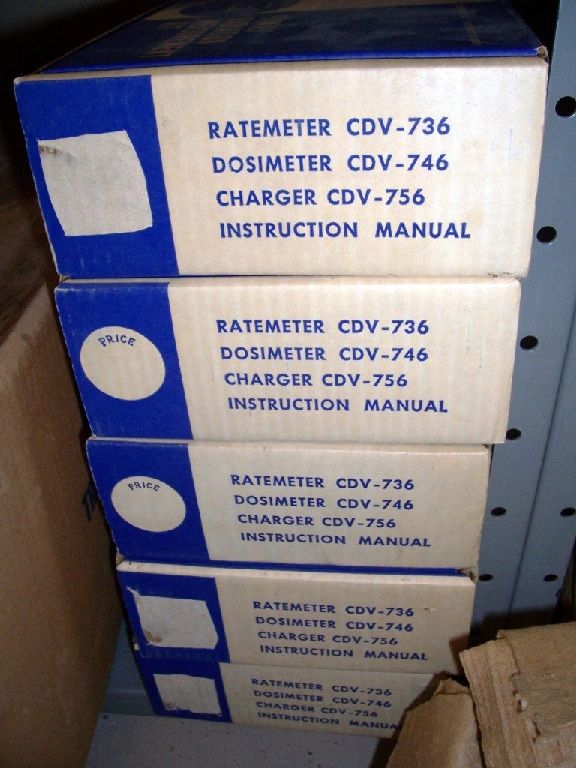

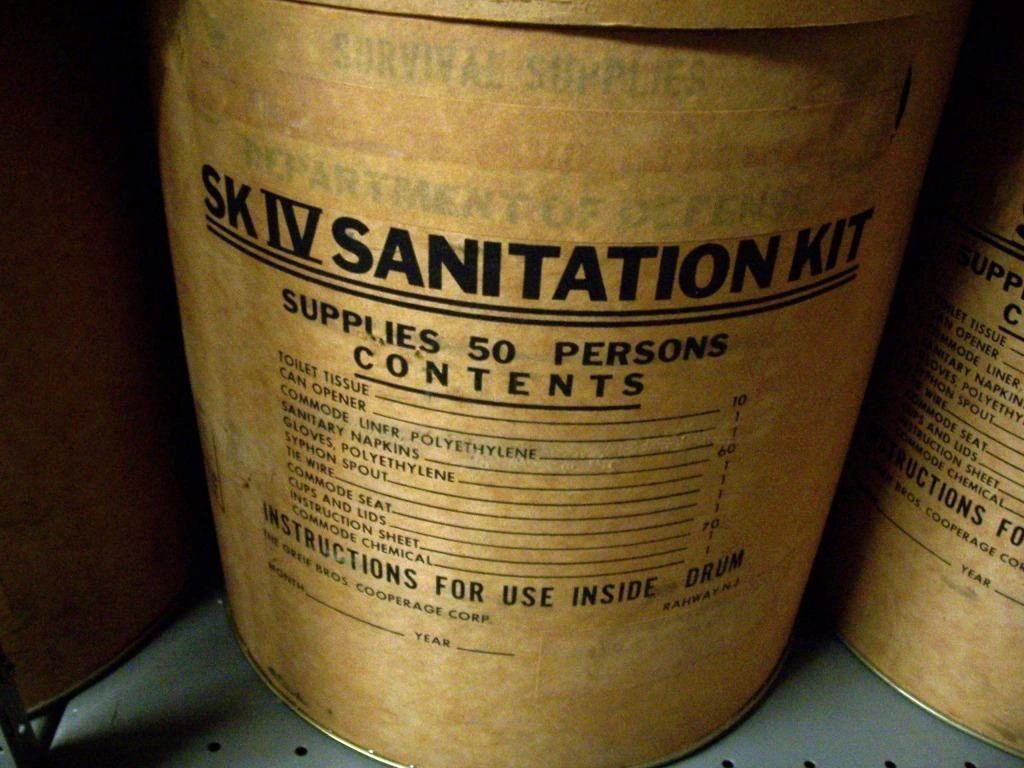

Adjacent to the cafeteria was a room stocked with survival supplies including food, cots, blankets, razors and shaving cream,

radiation survey equipment and survival manuals.

Clothing was available for contaminated workers including dozens of boxes of brand new

Converse sneakers, c. 1968!

These underground facilities generally used hoists to bring equipment into the facility rather

than elevators we assume because it was nearly impossible to harden an elevator.

Access corridor.

Above ground:

This tower used to support AT&T microwave communications antennas that provided a back-up comm path for the underground coaxial cable.

This tower used to support AT&T microwave communications antennas that provided a back-up comm path for the underground coaxial cable.

Gamma ray detector. In the background you can see one of the air exhaust gratings.

\

\

A nuclear blast detector located several hundred feet away from the facility.